Moulage sous pression du zinc parts is another mostly popular alloys that are used in die casting process. Zinc alloy can be casted to precision tolerances, have thinner wall sections, complex shapes and much longer tool life. Die Castings China has the capacity to produce pièces en zinc moulées sous pression with a wide variety of in-house plated and/or painted finishes. Our goal is to deliver your zinc die casting product exactly to print specifications. Although aluminum and zinc die cast parts have a larger demand in the OEM marketplace, our IATF 16949 certified manufacturing facility has several Lktech zinc die casting machines. These machines allow us to supply engineered die casting products that range in size from several grams to nearly 45 pounds.

When to use Zinc die casting instead of Moulage sous pression d'aluminium Parts?

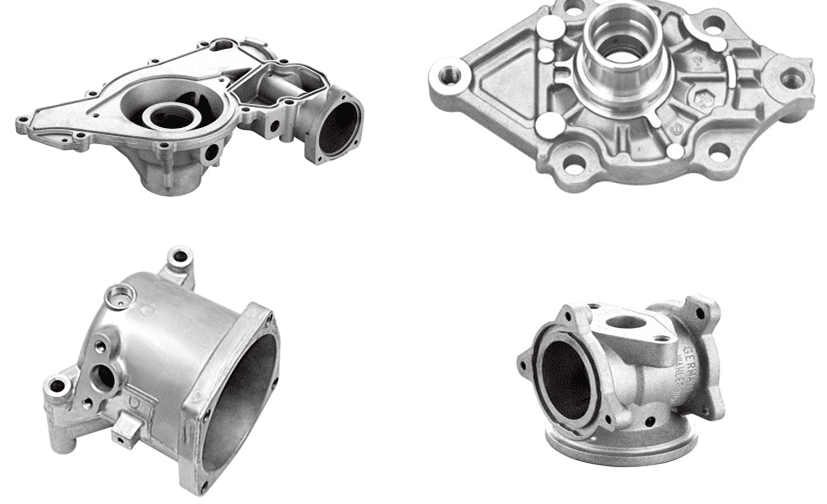

In addition to our first-class zinc die casting machines, our seasoned QC engineering staff interfaces with warehouse production to detect any problems and inspect the product for any defects. Zinc alloy has improved surface toughness and hardness making it an ideal alternative to machined, pressed, stamped and fabricated items. Zinc alloy die casting parts are known for their toughness over competing materials and processes. The overall yield strength of this die casting material is 15 times more than aluminum die casting alloy and magnesium die casting alloy. The alloy strength is a primary reason why the zinc die casting process is commonly used for gearbox housings, windows components, hardware compoents, electro-mechanical applications and other housing types.

Compare to both aluminum die casting and zinc die casting, both of them havea its advantages and disadvantages, normally some of big alloy parts are made in aluminum alloys and some of small metal alloy parts made in zinc alloys, but this is not always like that. on that other hand, some of metal parts that needs high quality surface finish such chrome plating, nickel plating, to improve the surface quality that they may use Zamak alloys as well.

If you have a project in hands and not sure which alloy materials that should be using, you may contact us, we will review this for you and give your the best options, if you have a project that needs both aluminum and zinc die casting products, you are send us your drawing, so that we could quote you in 24 hours.

Alloy Zamak-3 is currently the most popular alloy, but Zamak-7 will perform equally well and under certain conditions is superior to Zamak-3. Zinc die castings with alloy #7 have decreased magnesium properties, with increased amounts of nickel – with decreased impurity limits. Since there is a lower magnesium content, it has greater fluidity. As a result, this Zamak alloy types possesses better cast ability than #3. However, it still provides nearly identical physical, mechanical properties and dimensional stability. Zamak 7 alloy is very helpful when manufacturing larger size cast parts. Also, this material type is great for very producing complex shapes and for production that require superior hardware finish types. Using alloy Zamak-5 is limited to special cases when increased creep strength and material hardness are needed.

- Contrôle permanent de l'équilibre des machines et des "cellules en boucle fermée".

- Veiller à l'homogénéité des produits "d'un coup" à l'autre

- Accélère la correction de tout problème en cours d'opération

- Assurer la cohérence de la production jour après jour.

Avantages du moulage sous pression du zinc :

- Résistance et dureté élevées

- Très résistant à la corrosion

- Excellente conductivité électrique

- Conductivité thermique élevée

- Matière première à faible coût

- Faible viscosité permettant de réaliser des formes petites et complexes

- Précision et stabilité dimensionnelles élevées

- Excellente aptitude à la construction de parois minces

- Capacité de formage à froid, ce qui facilite l'assemblage

- Apparences visuellement attrayantes

- Résistance exceptionnelle à la corrosion

- Favorise la longévité des matrices

- Economique pour les petites pièces

Types de matériaux :

- Zinc 3

- Zinc 5

- ZAMAK 8

Moulage sous pression Gammes de tailles et de poids : 0,05-1kg Taille : 200*200mm

Liste des équipements

- (2) Lktech88

- (2) Lktech160

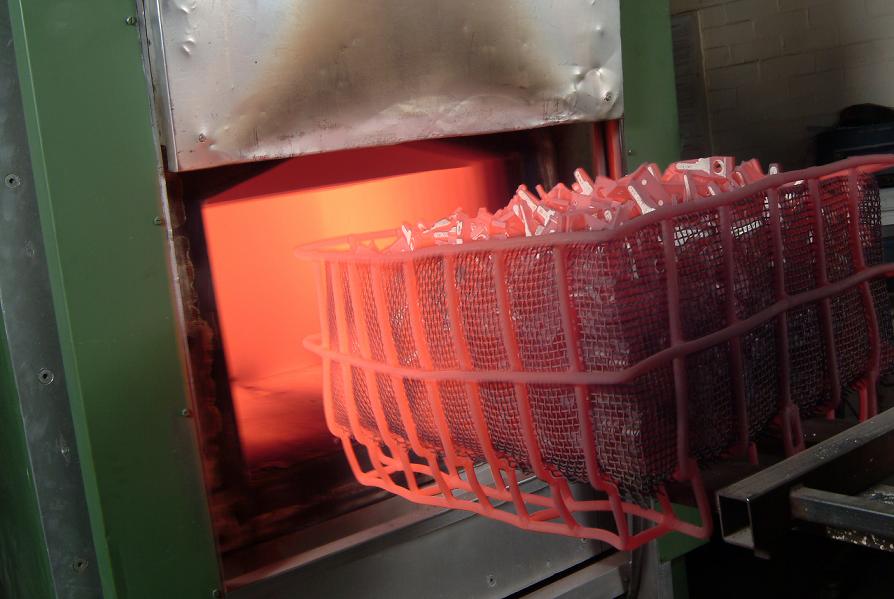

Four de fusion à concentration de gaz naturel

- (2) Shoei STM-500

- (1) Shoei ALM-500

If you are looking for a die casting manufacturer in China that have IATF 16949 certificate for your aluminum or Zamak die casting parts, you are welcome to contact us.