Lightness, non-corrodible attribute and versatility of aluminum contributes to its use in the contemporary world, making it one of the widely used metal. It is the catalyst behind industries that require performance and efficiency in aircraft and automobiles, construction and consumer goods. Nevertheless, simply casting or machining of the aluminum may not always suffice when […]

Automotive industry is at a point of fundamental transformation as it is facing a large demand of lighter vehicles, better fuel efficiency, and a non-stop evolution to electrification. At the heart of this change is the process of auto die casting which has transformed the designing and production of vehicles in the market. Injection of […]

Aluminum is heralded as one of the most useful metals in modern industries. Light, strong and corrosion resistant, it has become highly necessary in the automation and aerospace industries, the automotive industry as well as in opposite electronics and architectural design. Raw aluminum as much as it has many undisputed advantages has its shortcomings as […]

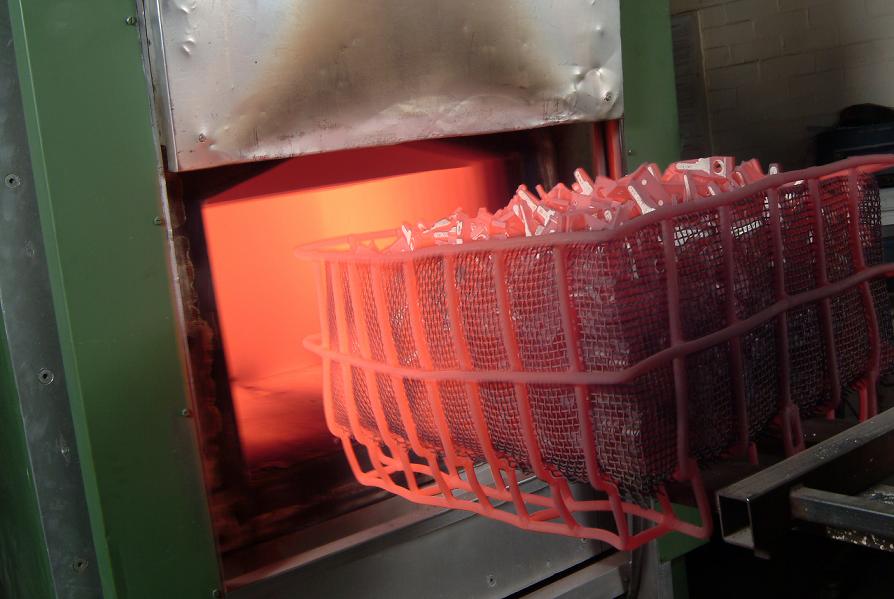

Aluminum has become one of the most significant engineering materials of the modern days with its rare properties of light weight and resistance to corrosion coupled together with versatility. These types of applications spectrums cover a wide range of use including aerospace and automotive structures, marine vessels, pipelines and consumer products, applications where aluminum is […]

The automobile business is arguably one of the biggest and most complicated manufacturing businesses in the globe and operates based on accuracy, solemnity, and affordability to provide automobiles under the world requirements in regard to performance and safety. There are many manufacturing processes that are used and casting takes a primary stage. Casting is a […]

In the recent years, the automotive industry has undergone significant transformations, owing to the rise in demands of efficient, sustainable and much-leaded performance vehicles. One of the key innovations in automotive manufacturing is aluminum high-pressure die casting, a process that plays a crucial role in producing auto parts die casting. Alzheimer has become the material […]

The car industry is not stable and there poses a great emphasis on the manufacturing of more efficient, durable, and environmental cars. One of the technologies that have spell out this revolution has been in die casting with a particular focus on automotive die casting which is now an irreplaceable technology in the production of […]

Metal plating is the most versatile and valuable of all the surface finishing processes in manufacturing and has many benefits that far transcend mere aesthetics. Depositing a thin layer of a metallic material over that of a base material, typically steel, copper or aluminum, manufacturers can: increase corrosion resistance; strengthen wear durability; enhance electrical conductivity […]

A significant change is being experienced in the automotive industry due to the necessity in ensuring more fuel-efficient, environmentally friendly and cost-effective vehicles. Aluminum is one of the most important materials that allow such a shift, especially when it comes to the production of automotive parts by the use of die casting. The lightweight, high-strength, […]

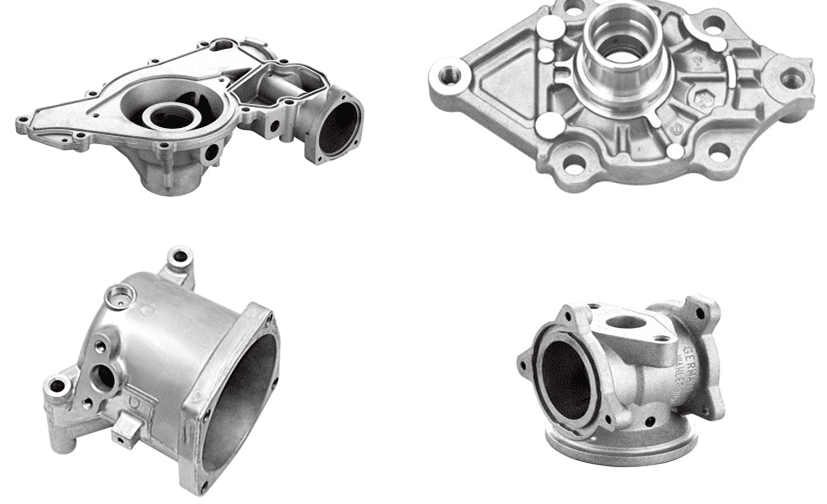

The thermostat housing, though apparently a minor part of the automotive engineering field, is an indispensable part that ensures the engines run properly. The thermostat is assembled in the cooling system of the engine, in a thermostat housing, and beautifies the thermostat, a mechanism of regulating the number of blowdowns to keep the engine in […]