Cars and trucks utilize many powerful components. One of the key processes that are involved in the manufacture of these parts is casting. Casting is, in a word, the making of metals into utilities. The auto world casting is helping to manufacture light strong and long last parts. We are today going to talk about […]

The aerospace domain represents the preeminent crucible for contemporary engineering innovation, wherein the interdependence of safety, performance, and efficiency enforces the strictest obedience to prescribed tolerances. Every architectural iteration whether constituted as an air breathing propulsion system, a telerobotic planetary surface expedience, or a multi role tactical platform—distributes features intentionally optimized to endure an antagonistic […]

Even though we may not be aware of it, aluminum die cast hardware is everywhere. Nothing is small, not even the cleats on a dock, or the joints in a garden chair or the brackets in a table. They ensure furniture is strong make docks safe and many products work well. Die casting involves forced […]

Cookware in any given kitchen is critical towards determining the success rate of meals. Whether it is fast meals on weekdays or large and sumptuous meals on the weekends, the pan or pot you cook in can make a big difference in taste and texture and even cooking capacity. Cast aluminum cookware has found a […]

As the fashionable food culture nowadays is fast-paced and the buyer needs to replicate their results with both home cooks and professional chefs, cast aluminum bakeware can be viewed as one of the sure energy sources. Cast aluminum offers the added benefits of better heat conductivity, structural strength, and flexible design opportunities compared to thin […]

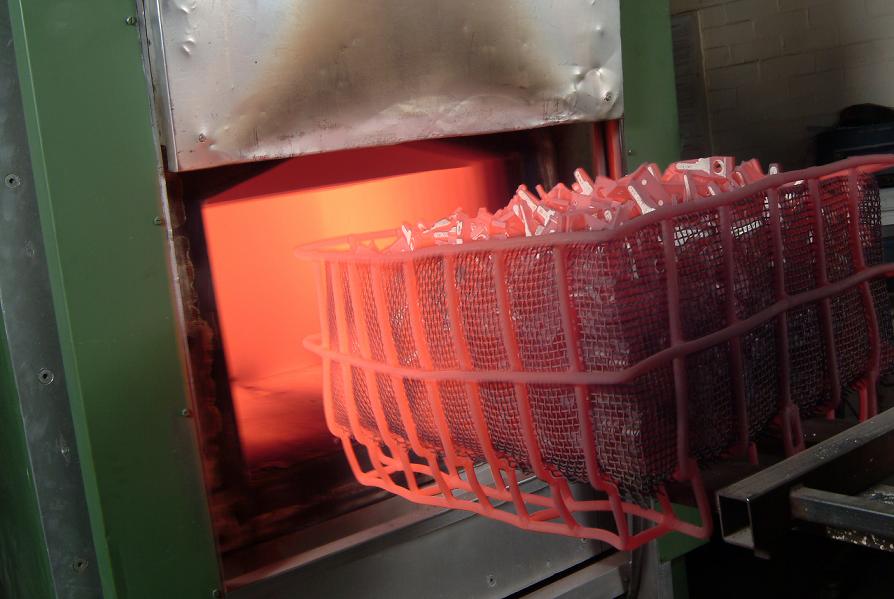

Metal casting in modern manufacturing has an imperative importance in carving out elements in the aerospace industry, industrial material equipments and consumer products. The two most common casting processes squeeze casting and die casting process. The two techniques will both yield high quality pieces that are produced with precision but it is the difference between […]

Die casting Aluminum has become one of the most commonly repeated types of machining procedure and has been sizzled through by the entire automobiles/ aerospace and industrial affluence as a lower cost process to create manufacture of plenty of complicated and long-term manufacture of goods. But although die cast aluminum has good strength, machinable and […]

Die casting is one of the largest motor industries in contemporary manufacturing, particularly in the automobile, aircraft, medical, and electronics sectors globally. Some of the manufacturers of die castings are also always improving and refining their processes as the industries develop to attain lightweight, durable and precision-engineered parts and components to meet the increasing demand. […]

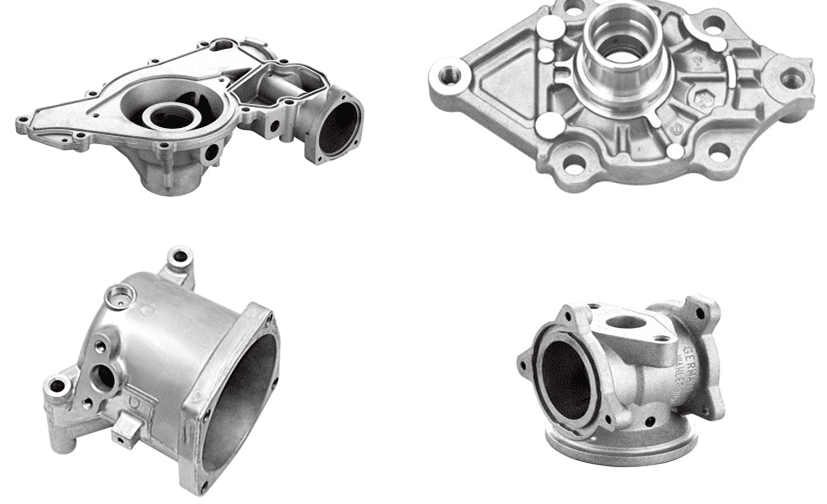

Automobile Industry has been one that is always on the cutting-edge in terms of developing technology. The automotive industry adopted innovation, precision, and efficiency throughout the course of the decades since Henry Ford invented the assembly line and up to the most recent inclusion of artificial intelligence into the existing production process. In terms of […]

Recent years saw a phenomenal growth of the robotics industry that introduced a new approach to our work thinking in terms of manufacturing, logistics, healthcare, aerospace, defense and even the world of consumer electronics still in imagination. One of the major factors pivotal in this fast revolution is that of the invention of strong, low […]