The production of aluminum extrusion is a very flexible and efficient way of manufacturing an object whereby a relatively unaltered cross-sectional profile is forced through a highly engineered die of steel on heated, aluminum alloy. It is like the familiar toothpaste tube squeeze it out of a tube and the toothpaste gets the shape of […]

Metal production is one of the foundations of human civilization that made it possible to construct tools, machinery, transport, and infrastructure. Casting and forging may be considered as two of the oldest and most common ways of forming metal into objects used throughout everyday life. Although the two processes are used to convert raw metal […]

Aluminum anodizing is an electrochemical finishing process which has become an effective means of substantially enhancing the characteristics of aluminum metal, by transforming its surface to an exclusively different one, a corrosion proof oxide, resistant to aging and although this oxide is thin, it is nevertheless impervious to corrosion. The anodized coating, unlike paint or […]

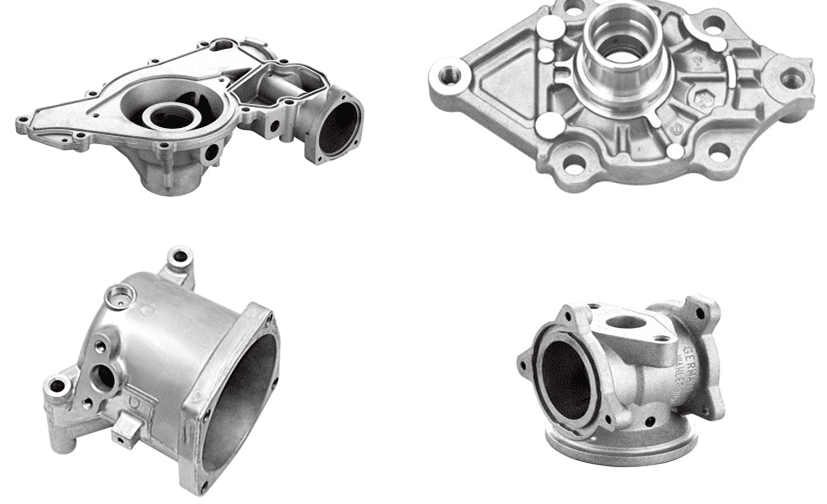

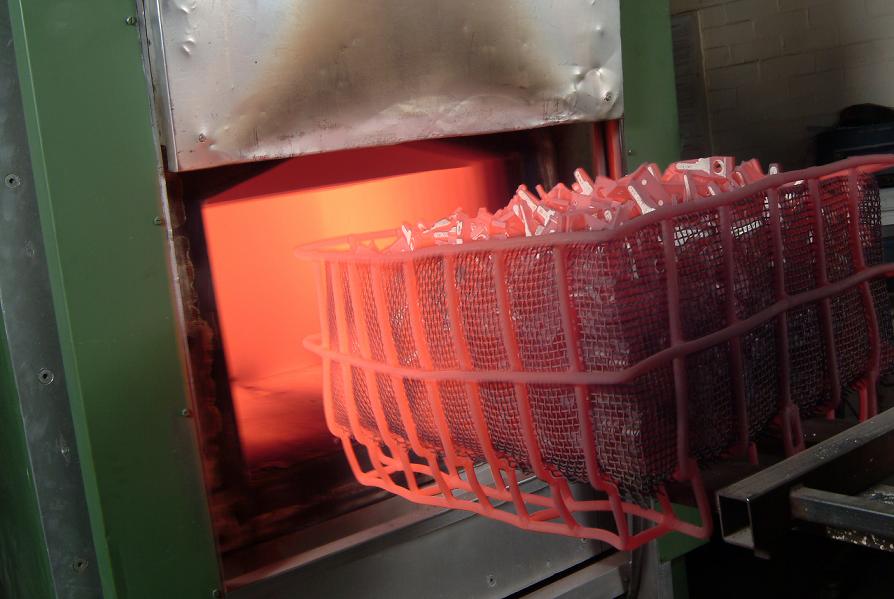

Aluminum is also one of the primarily produced metals in the world due to its light weight, corrosion free properties and its outstanding strength to weight ratio. Cast aluminum occupies an extraordinary niche in contemporary production and engineering and is part of the family of aluminum products. Lifelines, cookware, pistons, coins, engine blocks, structural frames, […]

Aluminum is a lightweight, high corrosion resistance, and favorable thermal and electrical conduction metal that is powerful and useful in various types of industries (aerospace to automobile industry). Nevertheless, in spite of these benefits, the comparatively low surface hardness and durability in wear and wear resistance of aluminum restrict its application to where there is […]

The automotive industry has been developing rapidly due to the worldwide need of lightweight, robust, performance-enhancing components. Among the ages-old manufacturing processes that led to this change, die casting is of utmost importance. We have used die casting to manufacture engine components, structural parts, transmission housings and other high precision parts used in vehicles and […]

Aluminum is a silvery-white, soft metal of low density which is one of the most abundant metals in the Earth crust and its role in the modern industry cannot not be overstated. Low density is one of the most characteristic strong points of it among other positive qualities. Mass of a material divided by its […]

Aluminum is the most flexible and a common metal that is seen in many industries associated with works, mainly due to its low weight, high strength and the ability to resist corrosion. Raw aluminum however wears out and is prone to oxidation. Aluminum is commonly anodized to strengthen its strength and improve its aesthetic beauty. […]

Aluminum has found its usage in most industries due to its lightweighted Ness, its strength proportionates to its weight and easy formability. But, as all metals it sometimes requires a surface to be added to or improved to help both in its functionality and appearance. Chrome plating is done on aluminum: by use of electricity, […]

Screen printing, also known as serigraphy, or just silk screen in the future, is a printing method composed of at least a few hundred years, but far predating the arrival of the digital, or digital world. Considered highly versatile, visually bold, and long-lasting, screen-printing finds application in several industries including fashion and fine art, electronics, […]