The past few decades we have specifically seen rapid growth in the auto industry automotive such as cars trucks and other heavy vehicles are designed and manufactured with lighter more durable and fuel efficient materials. One such materials that’s able to achieve this is cast aluminum. The people responsible for cast aluminum automotive parts are […]

Zinc die casting involves manufacturing processes for the production of metal parts which require complex shapes, high strength and durability. Strong and lightweight parts with considerable dimensional accuracy and good corrosion resistance which are manufactured at low cost are used extensively in automotive and aerospace industry as well as in consumer appliances, plumbing and electronics. […]

Aluminum on its own is highly versatile and is used in various parts such as automotive and architectural parts, household amenities, and even outdoor furniture, owing to its low weight, resistance to corrosion, and adaptability. However, tempered aluminum isn’t impervious to cosmetic deterioration, and wear and tear. Weather exposure also causes cosmetic damage along with […]

The lights on the streets in cities and even small independent projects have already been substituted by LED lights. The reason is simple. They are saving and can be used over hundreds of years. A solid body is behind each of the LED street lights safeguarding the light source. This is termed the housing. An […]

Surface finishing has always been important when it comes to improving the durability, performance, and aesthetics of manufactured parts. Out of the many finishing techniques, nickel plating is the most versatile and widely used, even gaining popularity over industrial plating. For electrolytic nickel plating, more focus is paid towards the improvement of metals’ corrosion resistance, […]

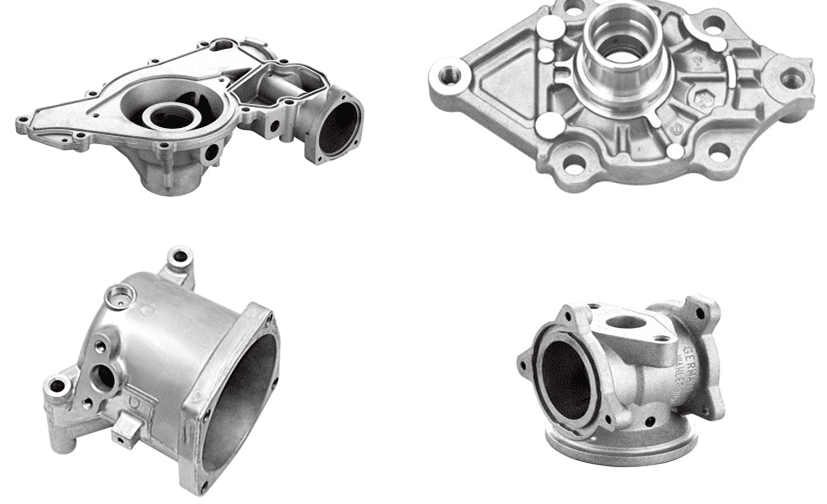

Aluminum can be referred to as one of the key materials in the contemporary range of cars. Virtually, all modern cars contain metal components of aluminum that include the engine and the wheels. These auto aluminum parts reduce the weight, strength, and efficiency of cars. Less fuel is consumed, less emission is created, and driving […]

Beginning its journey as a metal, aluminum was considered a precious metal due to its lightweight and durable nature. Time has proven the corrosion of aluminum as a marvel of durability. As such, its importance in the aerospace, automotive, construction and consumer electronic industries is indisputable. Nonetheless, aluminum is physically inadequate in specialized applications requiring […]

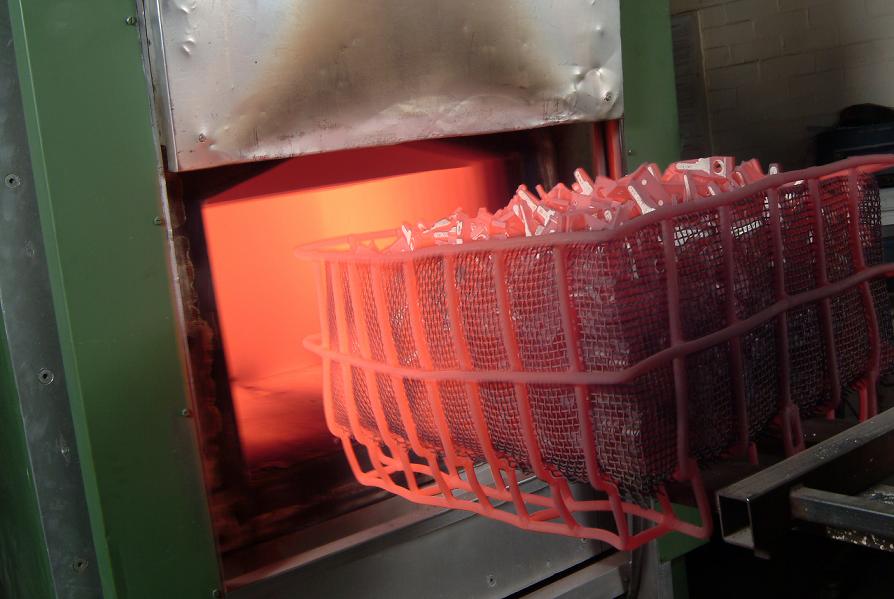

Semi solid die casting is an aluminum style which is used to produce powerful and accurate parts of aluminum. Under this process the aluminum does not melt completely, but exists in semi solid form as a thick slurry. This mix will easily fill the mold and occupy the space without incarcerating a lot of air. […]

Aluminum is appreciated across the world for its numerous applications and light weight coupled with resistance to rust and corrosion. To make aluminum stronger, manufacturers often anodize it which enhances its surface and gives it added protection. Aluminum anodizing does not merely help with functionality, but it also elegantly beautifies the anodized aluminum which uplifts […]

Relatively few techniques have withstood the test of time like sand casting. With the rise of advanced techniques such as additive manufacturing and CNC machining, sand casting still remains a vital process in the field of metalworking. The ability to create complex, massive and sturdy components using sand molds still proves beneficial to industries requiring […]