The past few decades we have specifically seen rapid growth in the auto industry automotive such as cars trucks and other heavy vehicles are designed and manufactured with lighter more durable and fuel efficient materials. One such materials that’s able to achieve this is cast aluminum. The people responsible for cast aluminum automotive parts are undoubtedly skilled and well cultivated.

The impact of chosen cast aluminum automotive parts manufacturers falls greatly on sourcing, engineering, and supply management. In this article we discuss the adverse effects of poor quality material on the supply chain and costs that stem from it as well as the correct partnership to foster with cast aluminum automotive parts manufacturers.

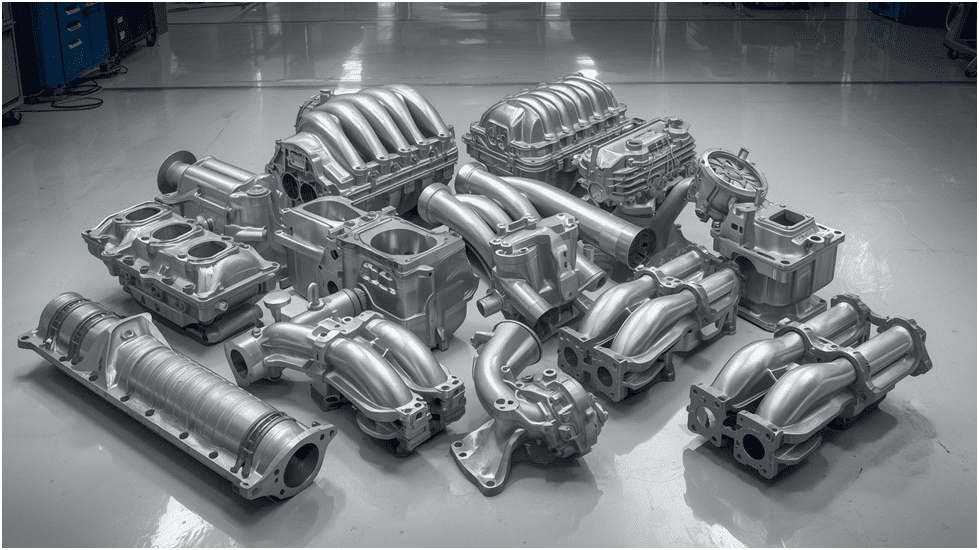

Why Cast Aluminum is Essential for Modern Automotive Parts

In modern technology, the most preferred vehicles are the ones constructed with aluminum, but for what reasons?

Strength and Weight Advantages

In the history of automotive engineering the part which has been the most used and the most produced is the steel part. While it has earned its status for its undeniable strength and reliability, the one disadvantage it has is its weight. The weight of the vehicle has a direct impact on the fuel consumption, emission, engine and suspension strain of the vehicle. This is the very point where the presence of aluminum and cast aluminum makes its impact. Lightweight cast aluminum is stronger than steel because of its strength to weight ratio. This means, the vehicles can be produced with the aluminum cast automotive components which makes the vehicles stronger at the same time lightweight.

Apart from the obvious advantages that the EV’s have, the fact that they need less energy to function proves the ratio of fuel consumption and emission efficiency to be more positive. The most cast aluminum automotive parts manufacturers are partnering with EV manufacturers because of the positive impact and synergy their partnership has with the EV market. With the above advantages being highlighted, it can be concluded that in the future, the vehicles which are manufactured using EVs will serve efficiency at the maximum and consumption at the minimum.

Just like weight, strength also matters. Cast aluminum components can endure stress, vibration, and loads. Parts like suspension arms, brake calipers, and wheels have to carry weight while also being able to withstand shook. Cast aluminum automotive components manufacturers, with the appropriate casting and machining, are able to provide components that are safe, long lasting and durable.

Heat Resistance and Durability

Engines, transmissions, and brakes use lots of energy and, consequently, create a lot of heat. Lesson learned, unmeasured exposed parts can warp, crack, and break faster than aims without countermeasures. It is because of Aluminum’s long and strong reputation that the automotive industry takes so much pride in the metal. The reason numerous components like engine blocks, cylinder heads, and even transmission housings may take and withstand extreme and rapid heating followed by massive cooling without any breakdowns, is because the structure absorbs and dissipates heat without allowing any build up.

Rusted steel is also weak and corroded which is contrary to the mechanical strength demonstrated by the cast aluminum components. Furthermore, aluminum is more corrosion resistant than steel. Automotive parts crafted through any cast aluminum process attain the most probable level of reliability, regardless the environment. No maintenance is necessary, and the hold of the automotive users and manufacturers is stronger when productivity and maintenance costs, due to extreme durability, are considered.

Another advantage is the property retention capabilities of cast aluminum even after prolonged use. Its shape retention capacity and functional reliability is maintained even after decades of use in high temperature systems. This is particularly evident in contemporary automobiles where the powerful and high heat generating engines have a much smaller footprint in comparison to their predecessors. In conclusion of these requirements, cast aluminum automotive.

How to Build a Long-Term Relationship With Your Supplier

After locating reliable manufacturers for cast aluminum automotive parts, developing rapport with them fosters trust which positively impacts outcomes and ensures smoother projects.

Clear Communication and Project Management

The importance of communication, especially in production, is of primary concern to any reputable cast aluminum automotive parts manufacturer. Any technological hurdles, timelines assigned to delivery, and production stage updates should easily be told to the customer.

Support for Design and Engineering Teams

Certain manufacturers of cast automobile components provide support even before production begins. Their suggestions on tool design, component shape, and substance used often lead to lower expenses and faster production.

Flexible Delivery and Logistics Solutions

These days, global supply chains tend to be complicated. Dependable manufacturing companies for cast aluminum automotive parts offer varied delivery schedules, storage opportunities, and quick shipment alternatives to minimize loss of productive work time.

Cast Aluminum Automotive Parts Manufacturers

Some manufacturers of automotive parts made of cast aluminum are:

Ningbo Yinzhou FeiYu Boat Accessories Co., Ltd.

| Detail | Info |

|---|---|

| Company | Ningbo Yinzhou FeiYu Boat Accessories Co., Ltd. |

| Founded | 2001 |

| Certifications | ISO 9001, IATF 16949 |

| Website | nbfeiyu.com |

| Phone | (562) 588-1520 |

| info@nbfeiyu.com | |

| Address | No. 123 Gongyi Rd, Xianxiang Town, Yinzhou District, Ningbo, China |

| Facility Size | 40,000 m² near Beilun Port |

| Equipment | CNC, laser cutting, robotic welding |

| Services | Custom part manufacturing from prototype to production |

| Industries Served | Marine, automotive, towing/trailer, construction machinery |

GC Precision Mould Co., Ltd

| Detail | Info |

|---|---|

| Company | GC Precision Mould Co., Ltd. |

| Established | 1999 |

| Certifications | ISO 9001 |

| Website | aludiecasting.com |

| Phone / WeChat | +86 131 4886 5556 |

| info@aludiecasting.com | |

| Addresses | 1) No. 30 Huan Zhen Rd, Qi Shi Town, Dongguan, Guangdong, China, 523516 2) No. 15 Baotang Rd, Qiaotou Town, Dongguan, Guangdong, China, 523520 |

| Industries Served | Automotive, aerospace, electronics, telecom, consumer goods, and many more |

Key Qualities of Reliable Cast Aluminum Automotive Parts Manufacturers

No two suppliers are alike. With reference to parts sourcing, the following are qualities you should consider for cast aluminum automotive parts manufacturers.

Certifications and Quality Standards

Quality is crucial when sourcing parts for the automotive industry. Car manufacturers and Tier-1 suppliers are required for each part to meet the strict standards for safety, reliability, and environmental protection and sustainability. Per every automotive cast aluminum parts manufacturer, the evaluation processes inherently include the criticism, or the reproach, of a qualification.

An issuer with ISO 9001 certification proves the existence of meticulous processes, correct documentations and continuous improvement of the quality. Thus, the defect potential is less, and every shipment deserves confidence for the customers. In addition to ISO 9001, a more important certification is IATF 16949, which goes for the automotive sector. Like ISO 9001, this standard is the addition of control which is essential for production, testing and cross tracing. Hence, it is safe to remark that manufacturers of automotive cast aluminum parts with IATF 16949 certification are reliable and satisfy the needs of automotive OEMs and Tier-1 suppliers globally. Also as important, if not more, is the management of the environment’s surroundings. A number of customers expect. These reliable and accountable manufacturers make excellent long term partners.

Full In-House Production and Machining Capability

The foremost benefits associated with the cast aluminum and automotive part manufacturers is the ability to manage the entire manufacturing process in house. They have internal die-casting machines for the aluminum parts because they do not subcontract the work to another as

The process typically starts with modifying the tool and the die. Among all manufacturers, there are those engineers found who will design even complex geometry molds with utmost precision that are tailored to every unique need.

The succeeding step is the actual machining of the aluminum which is done with die casting machines. Die casting machines provide the needed precision, accuracy of the parts, and the level of surface finish which is required

After machining, the components of an automobile are further refined to address the needs of the tight tolerance every automotive part is required to be machined to. With advanced in house machining, the supplier ensures that the required holes, threads, and surfaces, are provided in the given time required for

Next comes surface finishing. Imperfections on the surface such as rough edges and burrs can impact the skill and operation of a part. Manufacturers are capable of providing uniform and smooth finishes on parts because of the capability of doing process internally. Some even enhance the strength and corrosion resistance of the parts by providing anodizing, shot blasting, heat treatments, and even powder coating which improves the overall appearance.

All these features integrated in one line minimizes the lead time by a significant amount as there is no parts shipping necessary to and from subcontractors. The communication in the project is streamlined because there is a single team that is in charge of the project. The lead time being set by the contractor is minimized unnecessary because of excessive costs and higher chances of mistakes that is set by the contractors.

Experience Across Automotive and Heavy Vehicle Industries

Experience that is long-term is crucial. Most reputable manufacturers of cast aluminum auto parts tend to work alongside automotive OEMs tier-one suppliers as well as the agriculture, construction, and defense industries.

Benefits of Partnering With a China-Based Manufacturer

China is among the highest in die casting and machining. Numerous die cast aluminum automotive components manufacturers are located in the country.

Cost Advantages Without Compromising Quality

Cost effectiveness is one of the primary reasons global buyers turn to China. China’s labor and production costs continue to be more favorable than in North America and Europe. This also allows cast aluminum automotive parts manufacturers in China to price their products competitively. These prices are often impossible to match by other overseas suppliers. Low price also does not equate to low standards. In the past twenty years, China’s manufacturing sector has modernized and heavily automated. Trained labor has also been put to use achieving high industrial standards. Advanced die casting machinery and precision CNC centers are often automated alongside inspection systems. These systems are equally advanced to those in Japan, the United States and Europe. Another advantage is scale. China’s unmatched manufacturing infrastructure has the highest supply chain density for tooling, raw materials and logistics. This drives the prices of materials lower cast aluminum automotive parts manufacturers are able to supply them on time. In addition, many suppliers are now able to offer value added services. In-house testing, design support and rapid prototyping are simple examples. These refine the development procedures for consumers and guarantee functionality pre-mass production.

Access to Advanced Die Casting Facilities

Recent years have seen Chinese automotive parts manufacturers cast aluminum as having made the most rapid developments towards modernization of technology and manufacturing infrastructure. Enhancements made are not meant to only improve the pace of production; they aim at achieving consistency and conformity to the global automotive industry optimal standards in the parts produced at the automotive. In this regard, the most important element is the modern die casting machinery. Manufacturers are increasingly using high tonnage machinery to die cast highly intricate and accurate components. Such equipment, at a minimum, must have the capabilities of controlling the pressure (in the system), temperature, and the injection speed of the casting to achieve optimum results in the strength of the slabs produced and their uniformity. Thus, the automotive industry clients are guaranteed parts that can withstand very challenging conditions. Apart from the die casting machines, Chinese suppliers have also increased the use of CNC machining centers the technologically advanced. Often, after casting, components must go through a lengthy process of being worked on to obtain precise dimensional and aesthetic requirements statement. In-house CNC machining guarantees that any engine block, any given set of transmission housings assembled, and any set of components to a suspension/ suspension parts assembled, etc, is manufactured as close to the given design as possible. Such a high order of repeatability is needed in the most recent produced cars and other vehicles, as a high degree of accuracy is needed for the most recent produced cars/ vehicles and other gadgets.

Strategic Location for Global Shipping

Working with Chinese cast aluminum automotive parts manufacturers also offer the benefit of being close to some of the busiest shipping centers in the world. Aside from this, along with some of the busiest international ports, the cities of Shenzhen, Ningbo, Guangzhou, and Shanghai are also at the center of China’s developed export industry. By being close to these cities, manufacturers of cast aluminum automotive parts are able to save time and reduce costs when shipping completed products to the ports. This enhances delivery speeds to customers across the globe. There are also options for air shipping for urgent orders, and typically, manufacturers are placed nearby international airports which receive high cargo volumes. This convenience allows buyers to choose between economical sea shipping, and quick air transport.

Ports and airports are just the beginning of China’s impressive logistics system. They have also put lots of money into the country’s highways and rail systems, and the country’s supply chain management serves. This also provides manufacturers effective ways to deliver raw materials into the factories, and transport completed goods into international markets. Less delays are the benefit for buyers from other countries.

Questions to Ask Before Choosing a Cast Aluminum Automotive Parts Manufacturer

Selecting the right supplier is not only about price. You need to ask the right questions before signing any agreement with cast aluminum automotive parts manufacturers.

What Industries Do They Serve?

Ask the supplier if they’ve worked with automotive OEMs or Tier-1 suppliers. Many dependable cast aluminum automotive parts manufacturers serve the electronics, medical, and aerospace industries as well, highlighting their versatility.

Can They Handle High-Volume Production?

Automotive projects usually involve large batches. Always check if the manufacturers of cast aluminum automotive parts can deliver the plastic parts as required without compromising quality.

How Do They Ensure Consistent Quality?

Find out about the quality systems, testing and inspection methods used. High quality cast aluminum automotive parts manufacturers will divulge their process.

Conclusion

Aluminum has a lightweight, durable, and strong performance, set an importance to be used in the automotive industry. These automakers, and Tier-1 companies, receive parts in a reliable, cost-effective, and high quality fashion. cast aluminum automotive parts manufacturers and suppliers have to meet the strict standards set globally. Aluminum’s characteristics such as heat resistance, strength to weight ratio, advanced production capabilities, and durability, impact the way modern cars are constructed. Chinese suppliers have sophisticated facilities, certifications, and a strong logistic network giving them the ability to sustain competitive lower cost while maintaining high quality. The business decision does not end there. This is a long term performance, efficiency, and innovation investment with a trusted partner. Companies are able to remain relevant in the industry, and supplier cast aluminum automotive parts which are in high demand, while keeping a competitive edge.